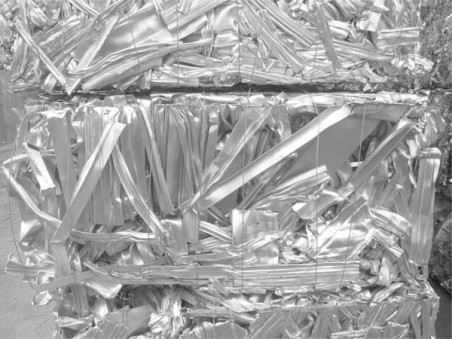

Aluminium Scraps export from Vietnam

In recent years, the processing of aluminum scrap (mainly chips and used drink cans) has attracted increasing attention. Aluminum scrap has a complex chemical composition based on aluminum (> 90%). Magnesium, zinc, Silicon, Iron, etc., are the main impurities. Sources of impurities are the composition of the alloy for producing drink cans (mainly, Al- Mg Alloy containing up to 3%–4% Mg) and mechanical impurities that enter into the scrap due to inefficient sorting, classification, and storage of the scrap.

Nowadays, all over the world, the main method of processing aluminum scrap is remelting in units of various types. The melt is usually cast into ingots. In some cases, the melt is granulated or gas atomized to produce powder of recycled aluminum (for example, APV powders in Russia). These remelting-casting technologies are rather power consuming.

Processing of aluminum scrap to powders and granules is an alternative to remelting scrap to produce ingots. The advantage of this technology is that it is a simpler and cheaper process of producing granules from recycled aluminum. The size of granules is easily regulated by the adjustment of grinders and varies from 1 to 10 mm. Such granules are used more effectively than ingots in ferrous metallurgy for steel deoxidation.